The Cost of 3D Printing vs Injection Molding

- Slant 3D

- Jul 30, 2019

- 3 min read

3D Printing is truly starting to scale up. It is often a comparable process to injection molding both in volume of parts it can produce and the cost of producing those parts. Currently, based on Data from projects done at Slant 3D, 3D printing is on average less expensive than injection molding up 50,000 parts and we are working to push it to 100,000. But that is an average. What are the factors that make 3D printing more or less expensive than injection molding?

Scale

If you make more parts they cost less per part. This is true for injection molding and for production FDM 3D Printing at large volumes. Many people have seen the graph below. The graph that shows that 3D printing costs remain constant regardless of volume. Nothing is more incorrect, those graphs are created by services with just a few machines.

Large scale 3D printing scales much the same as injection molding. The larger the job the better economics on materials. Below is a chart of a part that could be produced with Injection Molding or 3D printing. The part requires 40g of material. The Mold would cost $10,000 upfront. The vertical axxis is on the logarithmic scale. As you can see 3D printing follows a very similar curve to injection molding. And is in fact about 20% less expense up to 20000 parts and breaks even at about 45000 parts.

Warehousing and Inventory

While the graph above shows a situation where 3D printing and injection-molding eventually even out and have a mild price difference there is still the a cost that is not accounted for. Warehousing and lost inventory. It is estimated that 15-25% of inventory is scrapped each year because it is not sold. There are also the warehousing costs of that inventory which can add another 5-15% to the cost of a product. Even though 3D printing is higher cost than injection molding at very large quantities, its just in time capabilities ensure that almost no inventory is lost and very little of it every spends time in warehouses. Additive manufacturing allows a part to exist only in cyberspace until it is needed.

Design

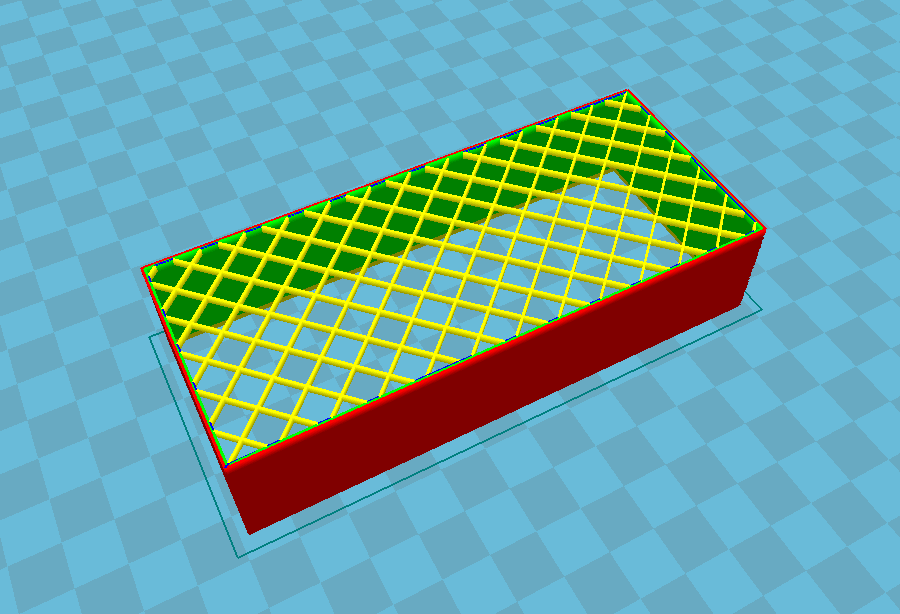

Design to minimize surface area, not the volume. This the general rule for FDM additive manufacturing. Volume is not really relevant to the cost of the parts. Surface area is. Surface area requires the most printing time and the most material. Internal volumes we are able to filling with internal lattices that maintain strength but do not add much material to the print.

The clearest depiction of this is with a simple cubic shape. With injection molding it would likely need to be design with ribs of some kind. But printing that design is expensive because it requires that the whole part be solid infill plastic. Which uses a lot of plastic increasing the print time and cost of the part. If the part is to be optimially designed for affordable additive manufacturing it should be designed solid. We will then use our various softwares to design an internal lattice that matches the strength of the injection molded ribbed part. But since the walls can be thinner it will often use less material is an more efficient to print. Saving cost

LittleBots is an excellent example of good design for additive manufacturing. Each part is simplified and monolithic. Allowing internal lattices to provide strength and light-weighting. For this reason they will never have to transfer to molds because the cost of 3D printing is always equivalent on a per part basis.

There are about 20 large design conisderations that can affect price of 3D printed parts. Including overall complexity, need for support, part size. But minimizing material and print time are the largest the best way to do that is to minimize surface area.

Now let us invalidate all this with a giant "it depends." The cost of a part, with either process, depends on the size, design, tolerances, and materials of that part. Some pieces will never be economical with 3D Printing. Some pieces will be impossible with injection molding. But there is an easy way to find out. Get a quote. We have qualified sales engineers who are ready to help you with the design and the quoting process to make sure that you are getting your product made correctly.

Comments